Design and Simulation

BAXY | Engineering design team utilizes a vast range of advanced software, such as Unigraphics, Catia, Ideas, and Pro-E, to deliver a quality product that meets customer expectations. The division is also capable of 3D modelling, prototyping, soft tooling, permanent tooling, and reverse engineering. For achieving excellence in the final manufacturing process, Magma Simulation Software optimizes & validates all designs.

A dedicated new product development centre adds a lot of value to product development, R&D, designing, machining, and validation. This makes it a preferred partner for global OEMs.

Low Pressure Die Casting

Low-pressure die casting is a process that involves the filling of moulds with molten metal using pressure rather than gravity. In this method, a riser tube forces the liquid metal upwards into the cavity from the holding furnace below the cast.

Gravity Die casting

Molten metal is poured from a crucible into a mould by gravity, without using pressurized gases, vacuums, or centrifugal forces in this process.

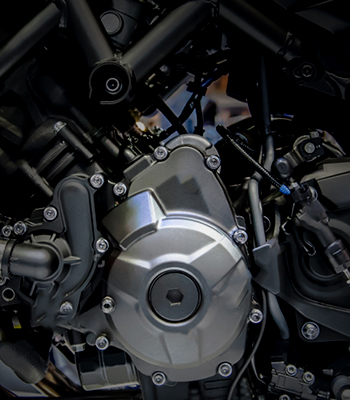

Machining

Our division is equipped with high-quality CNC machines made by top manufacturers such as Mazak, Makino, and Mori Seiki.

At BAXY | Engineering, we ensure that all products meet the highest quality standards by using tools like ultrasonic cleaning, SPM leak testing, CNC-controlled washing machines, and Millipore testing.

Assembly

As a customer-focused organization, BAXY | Engineering seeks to go the extra mile and offer fully assembled cylinder heads through automated assembly lines. In addition to these assembly stations, testing facilities are available for final assembled products. A large number of global OEMs order cylinder heads produced by BAXY | Engineering.

Quality Excellence

Lean manufacturing practices enable us to produce high-quality automotive components that are leaders and set the standard for automotive components. The goal is to achieve this through stringent process design, system implementation, and continuous improvement methods such as APQP and PPAP, as well as quality assurance methods such as POKA YOKE, used at all stages of manufacturing.

Six Sigma techniques are meticulously followed for problem-solving at various production stages.